Your 3D printing side hustle is gaining momentum. Orders are flowing in, customers love your work, and you’re making decent money. However, you may find you’ve hit a wall. Your printer runs 24/7, your spare room is overflowing with materials, and you’re turning down profitable orders because you simply can’t keep up. The solution isn’t buying another printer or working 80-hour weeks. It’s hybrid fulfillment, an approach that lets you scale your business without scaling your workload.

The Side Hustler’s Dilemma

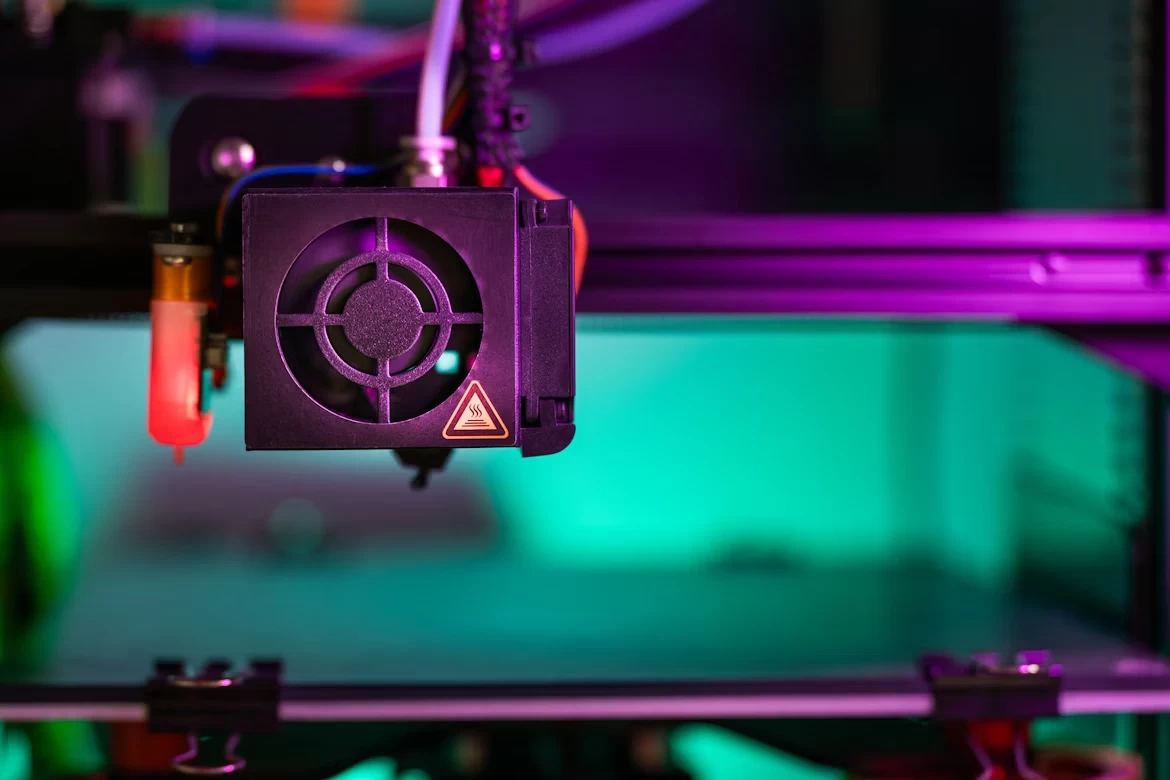

Most 3D printing entrepreneurs face the same bottlenecks. Time becomes your enemy when each print job takes hours, and you’re handling everything from design to shipping. Space constraints limit how many printers you can reasonably operate, especially if you’re working from home. Your output capacity becomes fixed, creating a ceiling on your earnings.

The biggest mistake is turning down orders because you can’t fulfill them. Hybrid fulfillment breaks this cycle by combining your core 3D printing capabilities with strategic outsourcing partners. You maintain control over your brand and customer relationships while extending your production capacity through trusted third parties.

What Hybrid Fulfillment Looks Like in Practice

Think of hybrid fulfillment as building a production network rather than a production line. You keep the high-value, specialized work in-house while outsourcing complementary services that eat up your time. Common tasks perfect for outsourcing include:

- Bulk heat transfer vinyl cutting and weeding.

- Direct-to-film (DTF) transfer printing.

- Garment decoration and embroidery.

- Order packaging and shipping.

Your workflow becomes fluid. A customer orders custom phone cases with printed graphics. You handle the 3D printing, send the graphics to a DTF partner for transfer production, apply the transfers yourself, and ship the finished product. You’ve doubled your output without doubling your equipment investment.

Finding the Right Partners to Extend Your Workflow

The success of hybrid fulfillment depends entirely on your partner network. Quality trumps costs every time. A cheap vendor who delivers subpar work or misses deadlines will damage your reputation faster than you can rebuild it.

Look for partners who demonstrate consistent quality, reliable turnaround times, and clear communication. They should understand your standards and be willing to work within your specification. Various printing services in Boise have emerged specifically to serve business and offer print-on-demand services that integrate seamlessly with custom manufacturing workflows. They handle the printing complexity while you focus on customer relationships and product development.

What to Consider Before Going Hybrid

Start with a cost-benefit analysis. Outsourcing reduces your per-unit profit margins but increases your total capacity and available time. Calculate whether the additional volume opportunities justify the reduced margin.

Brand consistency requires careful management when working with third parties. Develop clear quality standards, provide detailed specifications, and establish approval processes for new partners. Your customers should never know you’re using external service unless you choose to tell them.

Invest in systems that support hybrid operations. Order tracking becomes more complex when multiple vendors are involved. Customer communication tools help manage expectations when delivery timelines vary. Simple spreadsheets work initially, but dedicated project management software becomes necessary as you scale. Your 3D printing expertise remains your core differentiator. Hybrid fulfillment simply gives you the tools to scale that expertise without burning out in the process.