The meeting of additive and subtractive technologies is a major turning point for today’s rapid prototyping services. With 3D printing combined with CNC machining, engineers can develop their prototypes in a shorter period and make sure they have the correct features and surface. With dual methods, additive manufacturing helps with broad layouts in the beginning, and CNC machining is used for making the final design accurate and ready for use.

In cases where the design is complex, the production volume is small, or new designs are regularly needed, hybrid rapid prototyping fulfills all needs with maximum convenience. You can change the internal structure, use embedded elements, and plan cooling paths in the printed core, and finish the parts with machining for aerospace or medical standards.

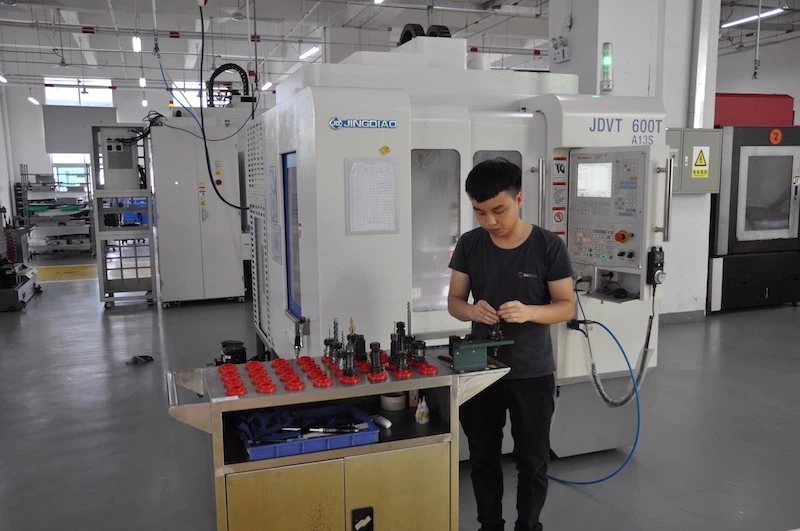

Consequently, custom CNC machining is not used on its own these days; it joins hands with additive methods to help bring ideas to reality and produce products ready for industrial use.

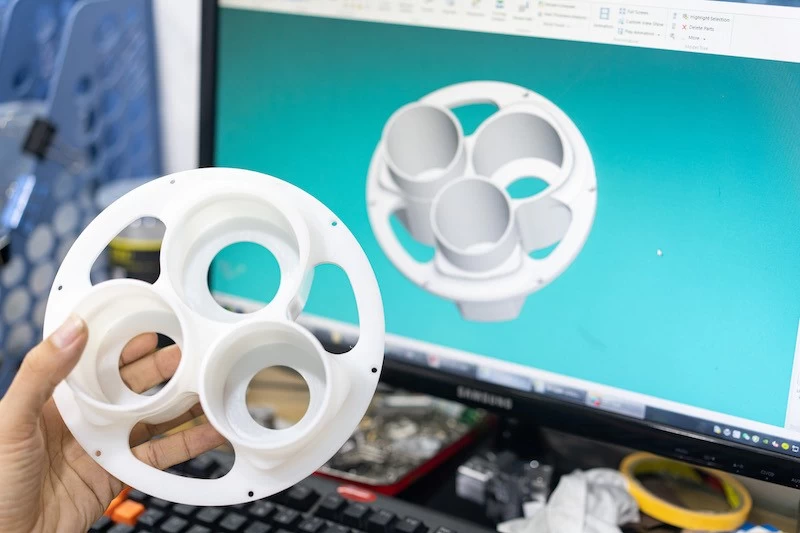

Design Flexibility via 3D-Printed Skeletons

1.Additive Freedom for Functional Geometry

3D printing gives engineers an easy way to start a design that would otherwise be impossible or very pricey to form with conventional technology. They are all easy to incorporate due to polymer or metal additive processes. If rapid prototyping services apply these features, lightening, absorbing energy, and inserting sensors into designs can be carried out early on in the design phase.

The benefit of additive-first approaches is that they allow designers to make flexible shapes. It is possible for engineers to review the mechanical, thermal, or fluid-flow properties at a small scale before they commit to making the product on a large scale. By using 3D-printed skeletons in rapid prototyping, it is possible to check parts such as turbine guide vanes or spinal implant housings very quickly. They give an accurate physical model for further improvements through the help of custom CNC machining services.

2. Integration with Simulation Tools.

This helps 3D printing to play a superior role in the area of rapid prototyping services. Before printing, engineers depend on simulation software to illustrate the flow of forces and how the material will be spread out. The skeleton offers both the shape and important functions for subtractive finishing. Preparing physical prototypes allows adding characteristics that assist fixturing or changing part position when they go on to be finished using custom CNC machining.

Ensuring downstream compatibility in planning the print brings about less waste and less time needed for fixtures in hybrid workflows. As a result, rapid prototyping services are very useful for aerospace and defense since reducing the cost of each step is crucial.

Final Fit and Finish via Custom CNC Machining Services

1. Achieving Tolerances Beyond Additive Limits

Designers find the flexibility of additive processes good; however, their accuracy and smoothness are not always sufficient. That’s why custom CNC machining services are needed. The parts are printed almost to completion, and then CNC machines add key features such as bearing seats, parts for light to pass through, and places for other parts to be mounted with higher accuracy. For most metals and high-performance polymers, this way of designing ensures accuracy and dependable structure. It allows the printing engineer to fine-tune the geometry using a CNC machine to boost mating and reliability.

In an aluminum housing that is printed, the apparatus for threads, alignment, and seals are manufactured with 5-axis CNC machining techniques. Such careful work is essential because if the interface fails in autonomous robotics or diagnostic imaging industries, it can ruin the entire system.

2. Toolpath Strategy and Registration

Proper registration is key to getting the best results when using hybrid processes. For custom CNC machining, CAM must be able to link with scan data or search for fiducial marks set in the prints during printing. After that, multi-axis machines use operations that spread stress evenly, minimizing the chances of deformation caused by temperature differences.

Advanced simulation of toolpaths is common when rapid prototyping services need to deliver work on a tight schedule. Using machining, approaches such as high-speed finishing, adaptive roughing, and dynamic tool engagement are applied just for the shape and material of the printed part. You end up with a working prototype that is machined and tested within days.

Application in Aerospace, MedTech, and Wearables

1. Aerospace Ducting and Lightweight Structures

Several aerospace ducting projects use hybrid rapid prototyping services to handle both the inside and outside parts of their assemblies. Fuselage ducts made of nylon or Ultem-based materials can be printed and later machined at their connection parts to fit inside the fuselage. Using the hybrid model makes it possible to complete jobs faster and gain the finish quality needed for pressurized systems.

Also, using custom CNC machining services allows for adding metal inserts, bushings, or getting the ducts ready for surface coating. Reducing manufacturing by printing most of the items and machining only a few allows aerospace OEMs to save both weight and costs without breaching certification rules. These modular workflows demonstrate the added use of rapid prototyping services to support flight-certified and load-bearing items.

2. Medical and Wearable Use Cases

It is very important to make quick iterations in both medical device housings and wearable tech products. Using hybrid rapid prototyping, engineers are able to check the comfort of the design, how electronics fit, and if the product works with the body in one round. Soft polymer can be printed to make the sensor casing, and it is post-machined afterward for sharpness when fitting charging or electrode parts.

Prototypes used in medicine can gain a lot from the use of both modes at the same time. Printing guarantees the frame fits the person perfectly, and using custom CNC machining ensures it is suited and cleaned for surgery. Since these industries need regulators to be satisfied quickly, hybrid rapid prototyping helps businesses produce more products.

Conclusion

By combining 3D printing and custom CNC machining services, hybrid rapid prototyping services compress development cycles, improve fidelity, and enable cross-functional innovation from aerospace systems to patient-ready medical devices.