Digital Light Processing (DLP) 3D printing is transforming the landscape of resin-based additive manufacturing. Unlike traditional stereolithography (SLA) or digital light processing (DLP), DLP utilizes advanced projection techniques to achieve superior speed, resolution, and efficiency. As industries demand higher precision and faster production cycles, DLP 3D printing is gaining traction in sectors such as healthcare, jewelry, aerospace, and automotive manufacturing.

What is DLP 3D Printing?

Digital Light Processing (DLP) 3D printing is an advanced resin-based additive manufacturing process that employs a high-resolution digital projector to cure entire layers of photopolymer resin at once. This technique differs from traditional resin printing technologies such as SLA, DLP, and masked stereolithography (MSLA), which either use laser-based scanning or selective projection. By illuminating entire layers simultaneously, DIP achieves faster print speeds and enhanced precision. DLP 3D printers are gaining popularity for their ability to produce highly detailed and complex geometries with improved efficiency compared to conventional resin-based methods.

What Are the Advantages of DLP 3D Printing Over Traditional Resin Printing?

DLP 3D printing offers several benefits over conventional resin-based methods:

- Higher print speed – Simultaneous layer exposure allows for significantly faster printing times compared to SLA.

- Superior resolution – Digital projection enables fine detail reproduction, making it ideal for intricate applications.

- Less material waste – Optimized resin usage minimizes excess material and reduces operational costs.

- Scalability – Suitable for both prototyping and high-volume production, providing flexibility across industries.

What Types of Materials Can Be Used in DIP 3D Printing?

DLP technology supports various resin types:

- Standard resins – General-purpose materials for rapid prototyping.

- Engineering resins – Designed for high-strength and heat-resistant applications.

- Flexible resins – Suitable for soft-touch components and wearable parts.

- Biocompatible resins – Used in dental and medical applications.

What Are the Best Applications of DIP 3D Printing?

DLP 3D printing is widely used in multiple industries:

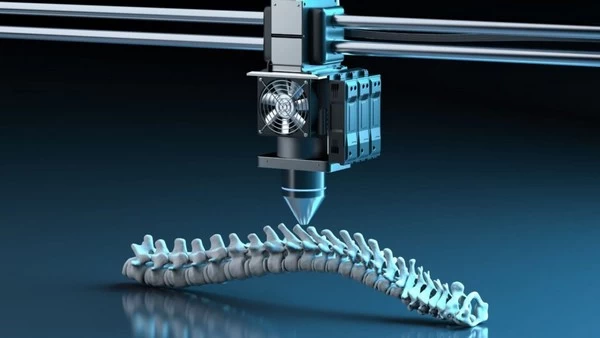

- Healthcare – Dental molds, prosthetics, and biocompatible medical devices.

- Jewelry – High-detail wax casting patterns for intricate designs.

- Aerospace – Lightweight components with precision engineering.

- Automotive – Rapid prototyping and custom functional parts.

What Are the Best DLP 3D Printers Available Today?

Some of the top-rated DLP 3D printers include:

- Raise3D DF2 - Digital Light Processing (DLP) 3D printer designed for rapid, high-precision printing with smooth surface finishes, ideal for engineering prototyping and low-volume production.

- Asiga Pro 4K – Precision engineering for industrial applications.

- EnvisionTEC Perfactory – Versatile for jewelry, dental, and engineering sectors.

- Phrozen Sonic Mega 8K – High-resolution printing with large build volume.

How Does DLP 3D Printing Impact Sustainability in Manufacturing?

DLP technology promotes eco-friendly manufacturing through:

- Reduced resin waste – More efficient material usage than SLA.

- Lower energy consumption – Optimized curing speeds reduce power consumption.

- Recyclable support materials – Advancements in photopolymers improve sustainability.

Conclusion

DLP 3D printing is revolutionizing resin-based manufacturing by offering faster print speeds, high precision, and reduced material waste. As industries continue to adopt this technology, its applications in healthcare, aerospace, and consumer goods will only expand. Businesses and enthusiasts looking to embrace cutting-edge additive manufacturing should consider DLP technology for its unparalleled efficiency and scalability.