Stereolithography (SLA), a 3D printing technology, stands out as a powerful and precise option. Like other most precise and versatile 3D printing technologies, it offers numerous benefits. This manufacturing process uses photopolymerization to create high-resolution objects layer by layer. It has the ability to produce intricate details, smooth surface finishes, and complex geometries with remarkable accuracy. In this article, you'll learn the benefits that make SLA a go-to choice for various industries and applications.

What is Stereolithography (SLA) 3D Printing?

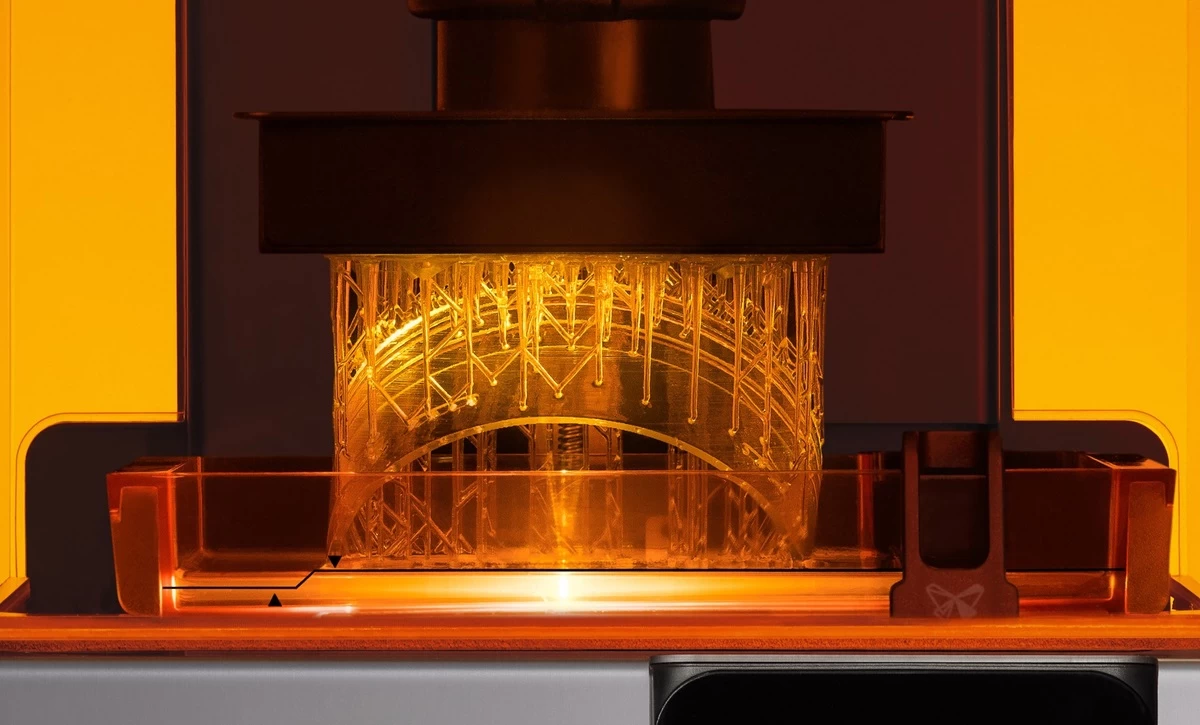

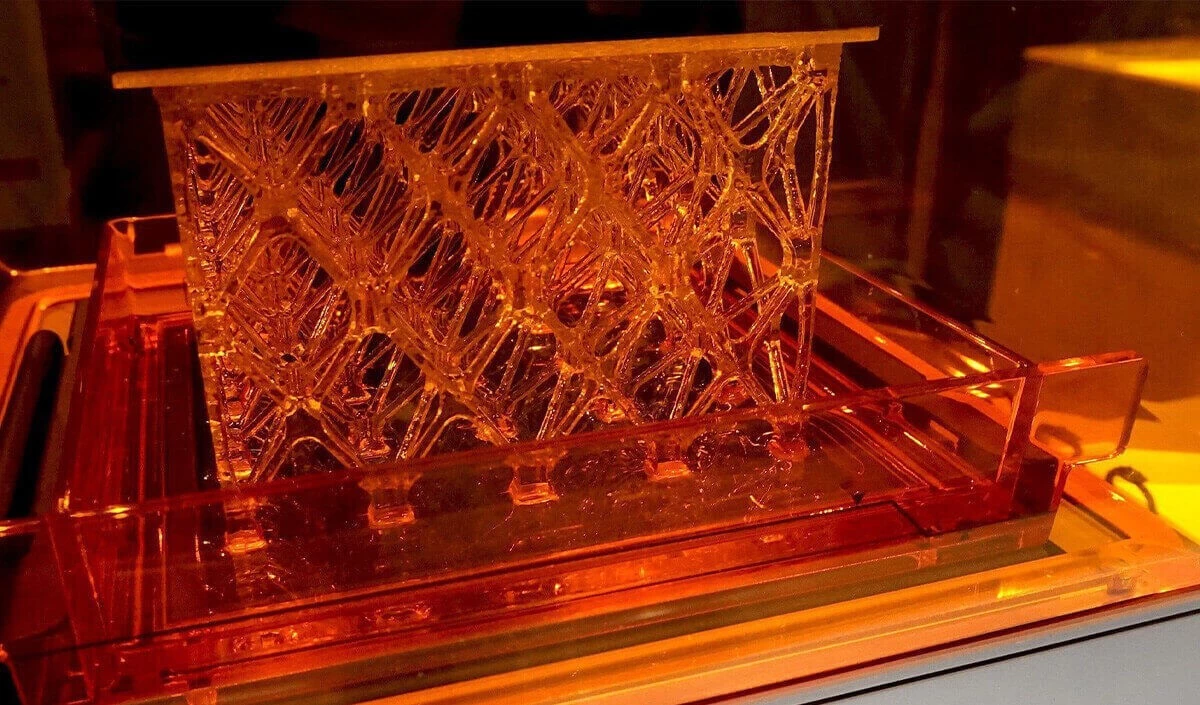

Stereolithography, often abbreviated as SLA. This 3D printing technology creates three-dimensional objects by curing liquid resin with ultraviolet light. This process, known as photopolymerization, solidifies the resin layer by layer to create the desired shape.

This technology is one of the oldest and most reliable methods of 3D printing. It is known for producing high-resolution parts with exceptional detail.

How does SLA differ from other 3D printing technologies?

SLA uses a UV laser to cure liquid photopolymer resin into solid plastic, layer by layer. It offers a wider range of properties and finishes than other materials used in 3D printing. Unlike Fused Deposition Modeling (FDM), which extrudes a thermoplastic filament, SLA uses a UV laser to selectively harden a liquid resin. This process creates highly accurate parts with smooth surface finishes.

The layer-by-layer curing process in SLA results in high precision and detail. SLA is particularly well-suited for creating complex, intricate, and smooth objects.

What materials are used in SLA printing?

SLA uses a range of photopolymer resins, offering flexibility in material properties. This resin can be formulated to mimic ABS, polypropylene, or even ceramic-like materials, providing options for a variety of applications. This technology excels at producing parts with intricate details, making it ideal for making concept models, functional prototypes, and even small-scale production parts in industries such as aerospace, automotive, and healthcare.

What is the SLA printing process like?

The Stereolithography printing process begins with a 3D model designed in CAD software. The model is then cut into layers, and the printer uses a laser to trace each layer onto the surface of the liquid resin. As the laser hits the resin, it solidifies, and the build platform gradually lowers to create the object layer by layer. Once printing is complete, the part is typically rinsed in a solvent to remove excess resin and cured further under UV light to achieve its final strength and properties.

What Are the Key Benefits of SLA 3D Printing?

It offers several advantages over traditional manufacturing methods and 3D printing technologies. SLA 3D printing offers several key advantages, including:

- Precision and detail: It produces objects with exceptional accuracy and smooth surfaces.

- Speed: It can significantly reduce prototyping time, allowing for rapid design iterations.

- Versatility: It can be used to make a wide range of materials, from engineering resins to biocompatible materials.

- Complexity: it's ideal for complex geometries and intricate features.

- Cost Effectiveness: While the initial costs of SLAs can be high. But it can offer long-term savings by reducing the need for tooling and setup time.

Why is SLA known for its precision and detail?

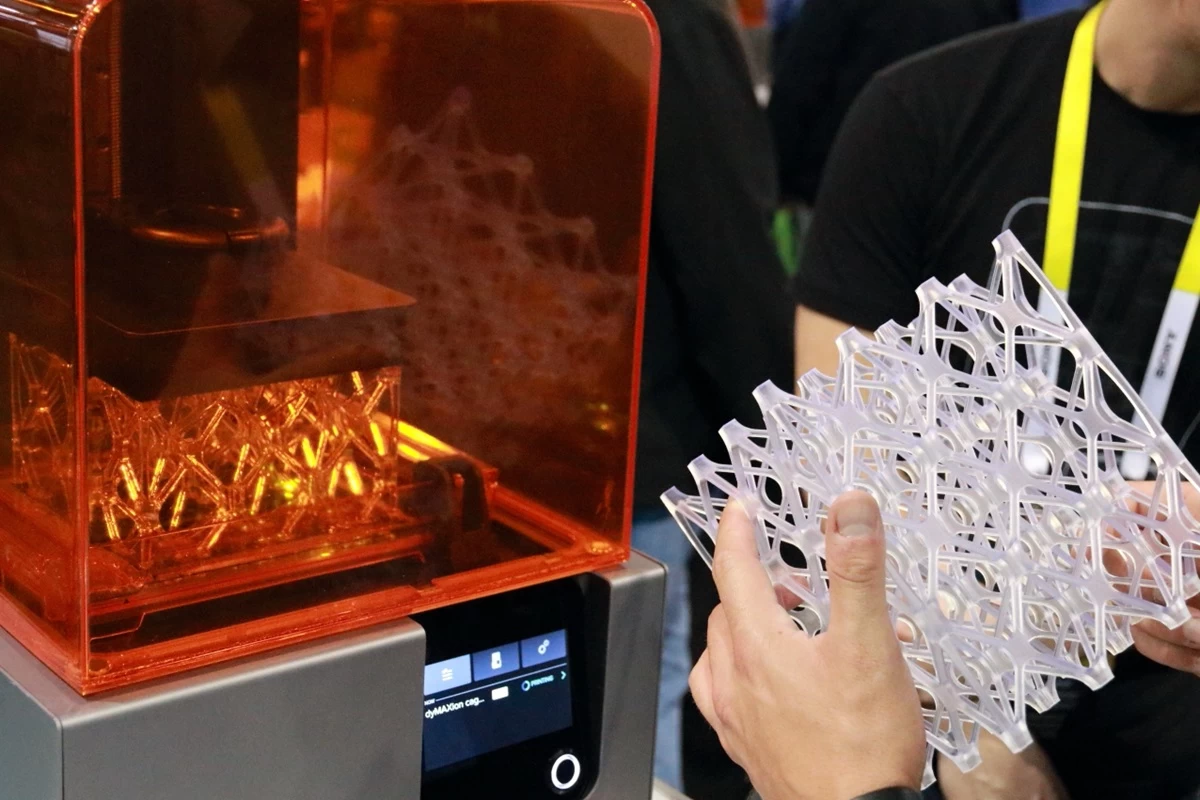

SLA 3D printing is renowned for its exceptional precision and detail. With layer thicknesses as fine as 0.05 mm and tight dimensional tolerances, it can produce parts that are nearly indistinguishable from injection-molded components. This level of accuracy creates intricate prototypes, medical models, and high-precision engineering parts.

How Does SLA Enhance the Speed of Prototyping?

SLA is also known for its speed, especially in prototyping. Because it creates objects layer by layer with precise laser control. The complex parts are printed faster than traditional methods such as CNC machining. By producing fully functional parts in around 24 hours, it allows rapid design iteration and speed to market.

What cost advantages does SLA offer over traditional manufacturing methods?

SLA offers substantial cost advantages over traditional manufacturing methods. By eliminating the need for expensive molds and allowing production directly from CAD files. This reduces upfront costs and enables on-demand manufacturing.

Who Can Benefit from SLA 3D Printing?

Its ability to create complex geometries with high accuracy and detail makes it a valuable tool for designers, engineers and manufacturers.

Which industries are leveraging SLA technology?

SLA is used in a wide range of industries, including:

- Aerospace: For creating complex components and prototypes. It can create lightweight, complex parts that meet strict performance criteria.

- Automotive: For rapid prototyping and tooling. SLA's accuracy and material flexibility make it a valuable tool in many fields.

- Healthcare: For producing medical devices and prosthetics. It is used to produce highly accurate surgical guides and dental aligners.

- Jewelry: To create custom jewelry designs.

- Consumer Products: For prototyping and small-scale product manufacturing.

How Can Hobbyists and Makers Utilize SLA Printing?

SLA printers are becoming more accessible to hobbyists and makers. They can be used to create a wide variety of projects, from custom toys and sculptures to functional items such as tools and accessories.

These affordable machines help hobbyists create high-quality, detailed items for personal projects, from intricate jewelry designs to custom figurines.

What role does SLA play in educational settings?

In educational settings, SLA 3D printing plays an important role in enhancing learning experiences. Schools and universities can use SLA printers to create accurate models for subjects like biology, chemistry, and engineering. Technology helps students bring their designs to life and fosters creativity and practical understanding of complex concepts. Furthermore, the ability of SLAs to produce transparent parts makes it valuable for demonstrating internal structures and mechanisms.

Conclusion

In the end, SLA 3D printing offers unparalleled accuracy, speed, and cost efficiency. It is a powerful tool for a wide range of applications, from professional industries to hobbyist projects. The ability to produce detailed, high-quality parts quickly and affordably is changing the way we think about manufacturing. Whether you want to create a detailed prototype, a custom part, or a functional piece. SLA 3D printing from XMAKE provides the flexibility and precision needed to bring your vision to life.